From manual processes and system errors to automation and a 40% increase in orders for personalized packaging.

ClientA company operating in the shipping and logistics industry

IndustryShipping and logistics

Scope of workDevelopment of a custom packaging configurator with 3D visualization, platform development and maintenance

Technologies used

0%

increase in packaging orders

0

people involved in the project

0

years of cooperation

About the Client

A leading courier company handling city, domestic, and international shipments. It offers dedicated e-commerce solutions, including a fresh food delivery service. The brand ensures easy integration with popular sales and accounting systems, enabling fast and reliable deliveries for business and individual clients.

Client's Problem

As a leader in the logistics industry, the client had advanced equipment for producing custom-sized cardboard boxes, but lacked a tool that would allow customers to fully utilize it. Additionally, the growing scale of operations slowed down the B2B platform and generated errors in communication with the warehouse system.

Identified problems:

- Lack of order automation: despite having a machine for producing personalized boxes, there was no automated interface for the end customer to place orders.

- Platform slowdown: with the growth of the business scale, the B2B platform worked slower and slower, and managing it from the administration panel was very difficult.

- Integration problems: unstable integration with the WMS system caused discrepancies in stock levels and a divergence in the number of orders between systems.

The goal of the project was to create a dedicated module for packaging personalization, automate the ordering process, and optimize the entire platform.

Proposed Solution

To achieve the intended goals, we undertook comprehensive development and optimization actions:

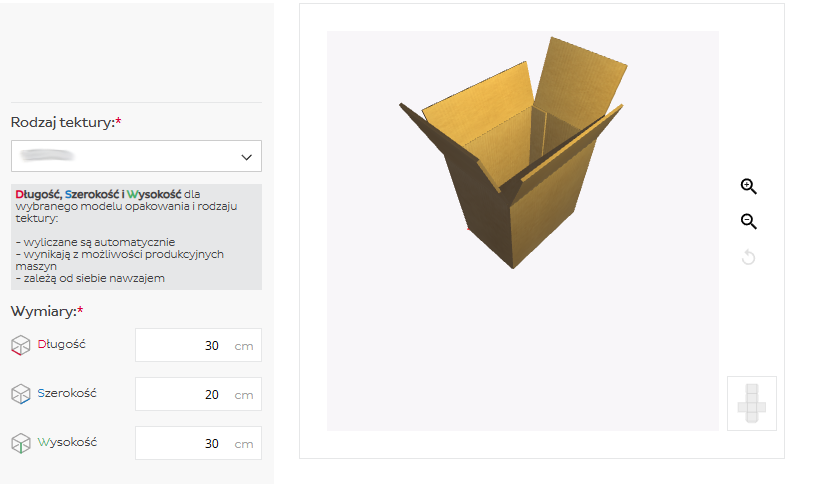

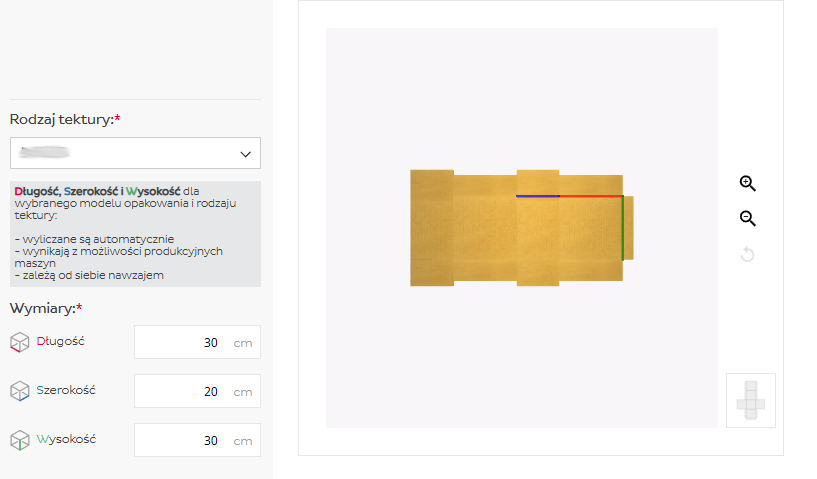

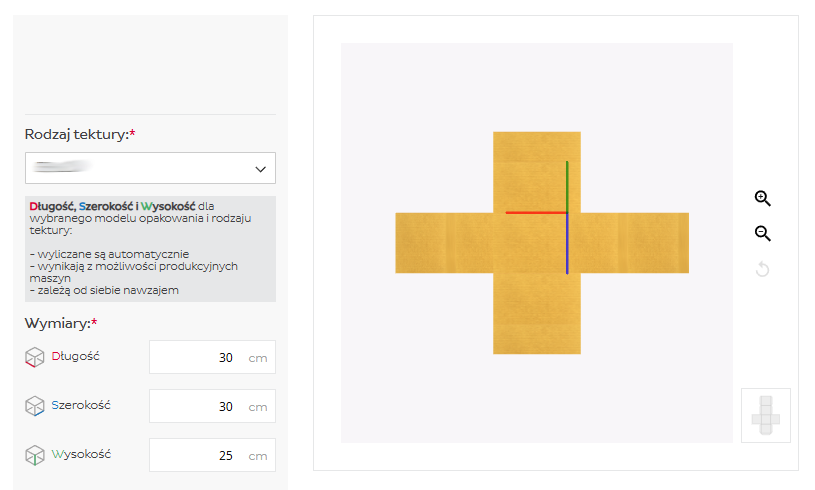

- Creating a packaging configurator: we created a dedicated module based on the Three.js library, which allows customers to configure packages of any dimensions, offering visualization in the form of a 3D solid and flat projections.

- Production automation: we integrated the B2B platform directly with the die-cutter interface. Thanks to this, orders were automatically sent to the machine, and the operator’s role was limited to supervision and acceptance of parameters.

- Optimization and stabilization: We performed platform optimization in terms of performance and implemented a queuing system to handle WMS synchronization errors, ensuring stability and reliability of processes.

Achieved Results

The implemented solutions brought measurable results that transformed the daily functioning of both the company and its clients:

- 40% increase in orders: The number of orders for personalized cartons increased significantly without the need to increase the engagement of the die-cutter operator.

- Radical platform acceleration: Loading time for order, customer, and product listings was reduced from 2-3 minutes to just 10-15 seconds.

- Elimination of errors: The problem of “lost orders” on the B2B Platform – WMS System line was completely solved.

"The new configurator allowed us to fully automate the ordering process for personalized packaging, which directly translated into a 40% increase in this type of order. Thanks to platform optimization and resolving issues with the warehouse system integration, we regained stability and control over the processes that mattered most to us."

Michał

Logistics Department Manager